ESTA AWARD

We are proud to announce that we have been awarded by ESTA the ESTA AWARD for 2017

PRESS ABOUT OUR TRANSPORT:

5 - 5

<

>

The history of our distinguished transport

Orders received

In mid-2013, we received a request to check it we would be capable of transporting a load with the diameter of six metres and the length of fifty metres weighing as much as ca. 220 tonnes from the port of Klaipėda, Lithuania, to a nitrogen plant based in Grodno, Belarus. The cargo was to be a reactor for production of chemical compounds at the nitrogen plant in Grodno. We were also informed that it was up to the possibility of transporting the reactor along the route in question whether an attempt to install it would be undertaken at all. The anticipated transport date was assumed to be the turn of 2015 and 2016. We had developed an action plan and started preparations described further on.

Transport capability assessment

As we received the request, we began examining options of driving from the Lithuanian port of Klaipėda to the nitrogen plant of Grodno in Belarus. We contacted a professional Lithuanian company handling transport of loads with nonstandard dimensions. The Lithuanian enterprise was also involved in procuring permits for transport of non-standard cargo, route planning and setting, measurements of road infrastructure and potential dismantling of its elements for the duration of transport. We agreed upon the action plan via e-mail and arranged for our arrival at Lithuania in order to jointly test the route along which the reactor transport could proceed. An analogical action plan was established with a corresponding Belarusian company, as we were to travel to Belarus once the job was done in Lithuania. Before leaving, we agreed upon the transport vehicles to be used, including specifics such as the number of axles, axle load, total set length as well as its height and width. We developed detailed drawings of such a set of vehicles, adding the relevant parameters and turning radii, which were of particular importance in this respect. Furnished with all the required technical details of both the vehicle and the load, we went to Lithuania and then to Belarus. The test run in Lithuania took us five days, for we had to measure virtually every single road sign installed along the route of the transit planned as well as every lamp post, power line, traffic lights, buildings next to roads or telephone lines. We had to take a peek under every bridge and assess if it was fit to drive on (which naturally was only a preliminary assessment, for the proper one must be conducted by expert surveyors) as well as measure radii of nearly every bend in order to establish the options for passage. Since the transport was to be handled under winter conditions, we were forced to account for road shoulders as well, examining their state and bearing in mind that they would be covered by snow afterwards, but what should also be taken into consideration was the inclination of roads with the prospect of black ice in mind. We would describe all these aspects in detail on the location, and then instantly make a decision whether we can go that way or not, for it would not be possible afterwards when sitting in the office a thousand kilometres away. At the end of the route on the Lithuanian side, we encountered a small bridge that we believed was impossible to pass. We drew up the necessary documentation and left the matter to be settled afterwards. The bridge was situated five kilometres from the Belarusian border. The entire Lithuanian section of the route was 576 km long. Once we finished working in Lithuania, we moved to Belarus. And as in Lithuania, every road sign, every power line, every bend, every bridge and every post was measured and described in detail so that the decision on the passage could be made. It was easier in Belarus, since local roads were broader, roundabouts were larger, there were no dirt roads involved and the route was shorter – only 398 km.

After the first visit to Lithuania and Belarus, we decided that the passage would be possible provided that we can solve the bridge problem and manage to obtain the road owners’ consent on transportation of such a large and heavy load.

The vehicle’s total dimensions were as follows:

Length = 75 metres

Width = 5.6 metres

Height = 6.8 metres

Total weight = 304 tonnes

Having returned from Lithuania and Belarus, we prepared a report and sent it to the ordering party. The new guidelines we received were clear:

1) Solve the bridge problem

2) Obtain road owners’ assurance to procure permits for passage of a vehicle of the aforementioned parameters.

Solving the bridge problem did not take us long as we established that, on the existing bridge, a steel fly-over bridge structure would be installed in a manner ensuring that the existing one would not be affected by any additional load. After three months of various attempts, we finally persuaded the road owners to grant us their approval required to procure a permit for the passage of the reactor-carrying vehicle. Another serious challenge we were facing was the matter of parking places, since we could only drive by night and had to park all day. It should be stressed that it is really difficult to park a vehicle of such parameters in a way not to disturb the traffic.

Preparing equipment for transport

The Goldhofer THP LT semi-trailers were used for transport purposes, forming a set of twenty six axles in total, with a gooseneck-design front trolley of twelve axles and a fourteen-axle rear trolley controlled by the Goldhofer turntable, propelled by its own hydraulic power pack and installed on a front trolley manufactured by Greiner. The preparations consisted in combing all units into two trolleys, installing the turntables on them, checking hydraulic, pneumatic and electric connections as well as oil levels in tanks. Toe-in was adjusted according to the length of the entire vehicle set. The rear trolley was prepared to be pushed by a ballast tractor.

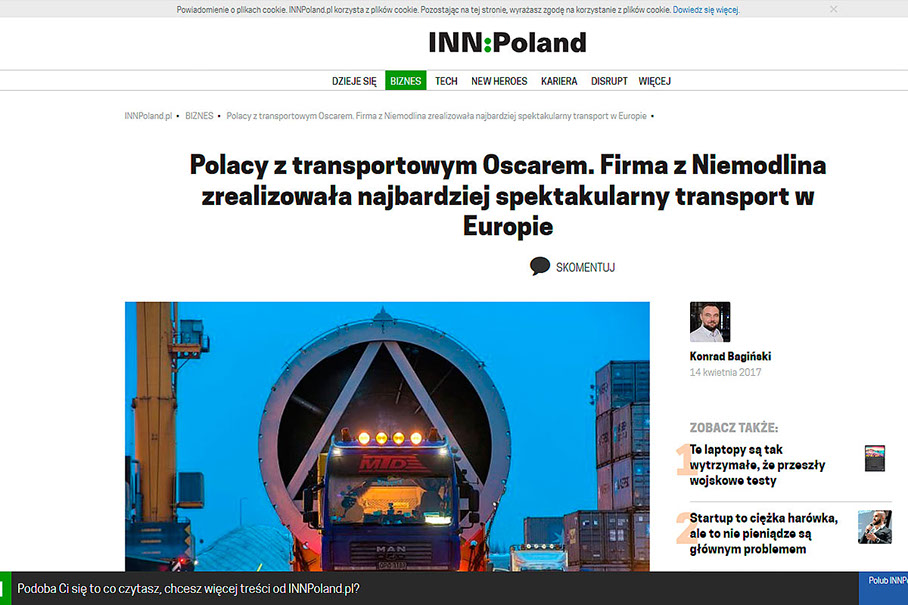

Loading at the Klaipėda port

Once the vehicle arrived at the Klaipėda port, the loading started. Two LIBHER harbour cranes with the hoisting capacity of 150 tonnes each lifted the cargo to an appropriate height so that our drivers would be able to push the trolleys underneath, one from the back and the other from the front. Having conducted thorough measurements, we placed the load accurately centred on turntables and double-checked the measurements, and since everything seemed fine, we attached the load to the vehicle by means of twelve-tonne chains. Once the attachment was completed, we released the cranes and made a short test drive on the port premises in order to verify all mechanisms in operation. Having installed warning lights and lights illuminating the entire load, we finally made the decision to leave the port and commence the actual transportation task. The time was 9.30 p.m., Sunday, 17 January 2016.

Driving through Lithuania

On Sunday evening, 17 January 2016, we began the transport project, departing from the port of Klaipėda and entering public roads. The first covered kilometre made us feel that we were properly prepared to the task, however, in comparison with the size of the buildings we were passing by, the load we transported truly commanded respect. In the middle of winter, the city of Klaipėda appeared as if it was hibernated. The streets were nearly empty, which apparently made our job easier despite very slippery pavement. Having initially got accustomed with the view of a huge vehicle slowly moving through this landscape, we did not encounter any problems. During the first night, we only managed to cover about twenty kilometres and arrived at the first parking spot, since it was impossible to reach the next stop at the same night.

The passage through Lithuania was well prepared and everything proceeded as planned, maybe except the weather which was a true challenge. Temperature fell below minus twenty degrees Celsius. Roads were very slippery posing a serious hazard while the vehicle was climbing slopes, especially considering all the pavement irregularities. There was also very strong wind and we were driving at night – all these factors combined did not really create friendly atmosphere. But we were prepared for unwelcoming climate, having equipped ourselves with warm clothes, additional warmers, winter caps, gloves, solid boots, even a field kitchen to prepare hot meals. Also the vehicles were suitably prepared for winter conditions and posed no problems, not to mention the most slippery road sections where we had to install chains on driving axles. We experienced minor problems while passing the fly-over bridge, since there was a bend in front of it and the road lacked a long enough section which would enable us to position the

vehicle in a straight line, making it necessary to approach the bridge directly from the bend which, bearing the glazed frost and the snow covering everything around in mind, was particularly difficult, especially since the bridge was only three metres in width, and so was our vehicle. We finally succeeded in passing the fly-over bridge and arrived at the Lithuania-Belarus border crossing.

Passing the Lithuania-Belarus border

In the morning of 22 January, about 10 a.m., we reached the border crossing between Lithuania and Belarus. It was closed, forcing us to wait until the border guard services appear on both sides. This particular crossing was not in service daily, being only opened when large loads, such as ours, were transported. Once the officials arrived, the customs clearance proceeded rapidly on both the Lithuanian and the Belarusian side of the border. We were permitted to drive in Belarus in daytime as well, and so the travel resumed shortly

Driving through the Belarus

We began exploring the Belarusian territory driving in very narrow roads, passing small villages, however, it was fortunately a very short section and after several kilometres conditions improved considerably. We entered wide roads, cleared of snow, which favoured slightly faster driving, allowing us to accelerate to ca. thirty kilometres per hour on average. For the sake of comparison, in Lithuania we drove fifteen up to twenty km/h, and wherever we encountered glazed frost we proceeded as fast as a walking person. What proved to pose a larger problem in Belarus compared to Lithuania was the cables hanging over roads, which took a lot of time to be raised or dismantled to Belarusian services. As in Lithuania, so in Belarus we were escorted by the police. As we drove in daytime as well, it raised considerable interest of both the local inhabitants, and the Belarusian flota. People would peep out of their homes and keep a close look at what was happening on the road. There was even a report in the evening TV news that no such transport had ever taken place in Belarus before. The only hindrance we had to overcome, although it really should not be considered an issue, was the necessity of by-passing an overbridge which proved to be too low. Fortunately, there was a plan B which we had prepared along with Belarusian services beforehand. We can certainly claim that everything proceeded according to the plan, and we experienced no serious problems.

Arriving at Grodno and unloading

On the very last day of the project, we were left with only a fifty-kilometre distance to pass, and so we departed, as each day, about nine in the morning in order to reach the nitrogen plant in daytime. We took the last section without hassle, and arrived at the gates of the destination plant around noon. We were greeted by the personnel, local people and the press. After polite exchange of some words of welcome, we were admitted to the facility premises in order to examine the unloading site. Having completed a short reconnaissance, we finally drove the transport fleet to the place of unloading. We proceeded with the unloading on the next day when two cranes arrived, each with the hoisting capacity of 300 tonnes. They were positioned at the front and at the back respectively, and after the cargo was lifted we managed to drive the trolleys away from underneath the load. Having quickly redeveloped the set and adapted the vehicles to normal driving conditions, we set off for the hometown. The operation had been successfully completed.

Conclusions

The only conclusion which comes to my mind is that there is really something to boast about, but boasting is certainly not in our nature. However, I would like to emphasise how proud I am of my employees, who worked hard to prepare and complete this transport task, achieving only positive results from the beginning until the very end. With the foregoing in mind, I am expecting a bright future for our company.

Kazimierz Skuratowicz

test